To Question 1: The Multiple In-Winding, Convoluting Flow Process.

If water containing coarse suspended matter is first stirred around in a glass beaker and afterwards left to rotate by itself, then the suspensions concentrate themselves in the axis of the rotating cylinder of water caused by the stirring. This well-known natural phenomenon is already being evaluated technically in the circular sand-capture machine by the Geiger Company, Karlsruhe and in the 'Hydro-Cyclone' of the Stami-Carbon Company for the separation of suspensions from water. In both cases the contents of the circular containers is caused to rotate by the tangential supply of the liquid, which can be con- sidered to be the cause of the self-ordered concentration of suspended matter in the axis of the vertically rotating cylinder of liquid. However if water is conducted from a large container into an inlet pipe and is set in a faster or slower rotation above this, a suction funnel is formed, which is deeper or shallower according to the velocity of flow prevailing in the outlet pipe. Attentive observers can often watch the formation of such vortexial funnels at the outlets of basins and baths. The spiralling of the water in the pipe, evolving from the inlet in the direction of the outlet pipe and the forward motion of the water in the outlet pipe itself, now generate as a result of these reciprocal influences, a flow-through process composed of the simultaneously combined effects of several 3-dimensional space-curves, which can be made visible in the following manner.

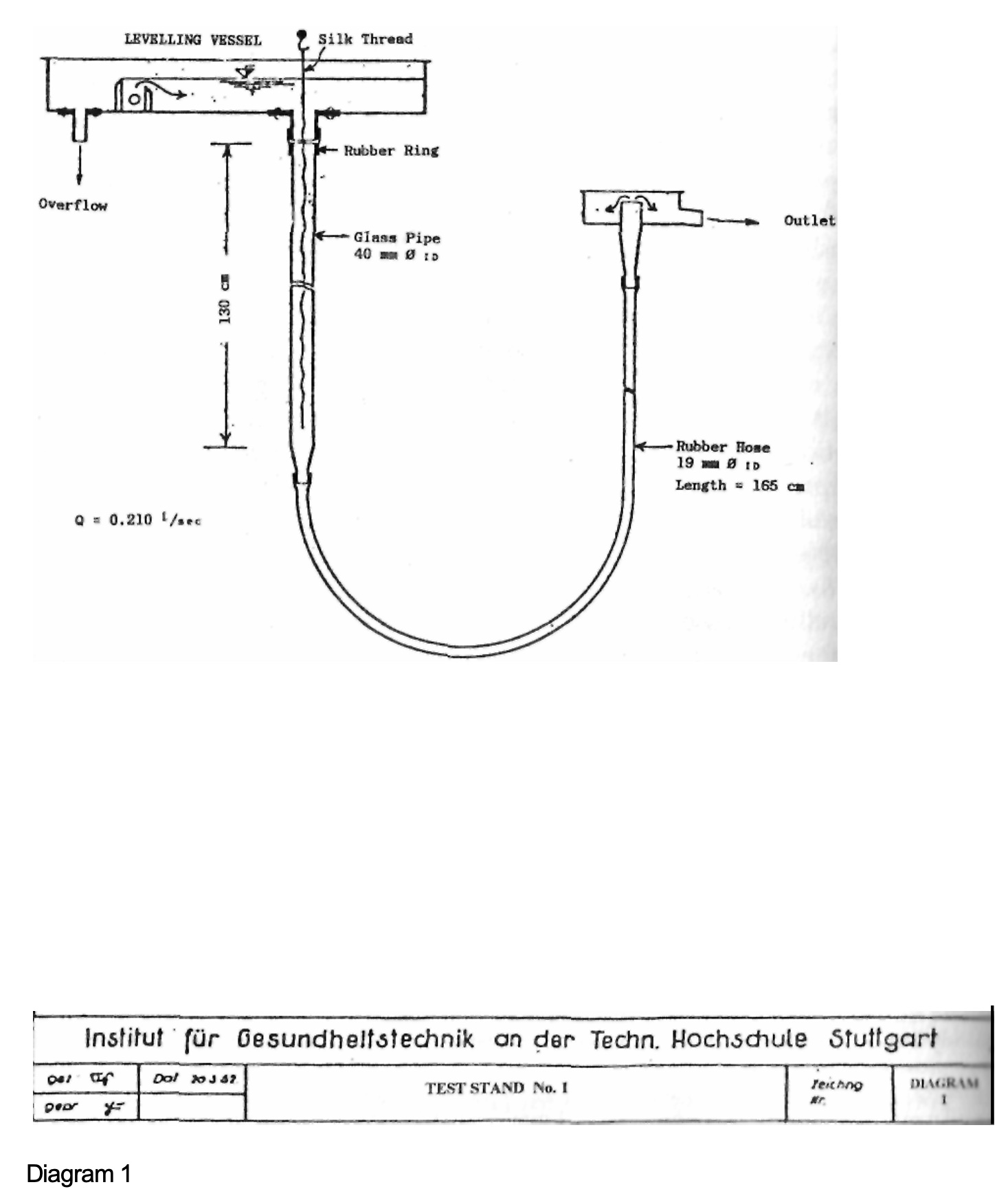

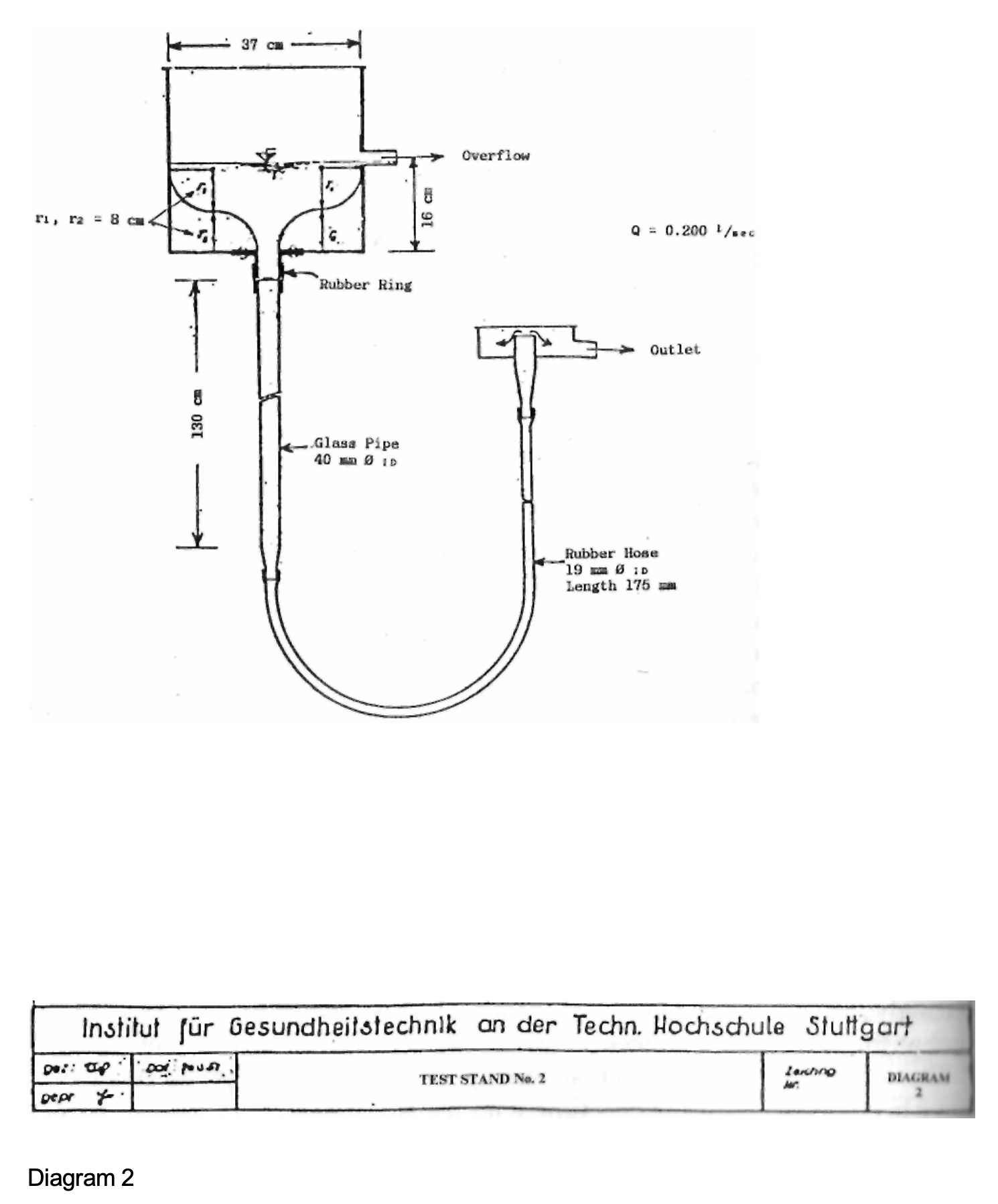

Water flows from a vessel with a constantly maintained water level (levelling vessel) into a glass pipe of 40 mmOID1 and onwards by means of a rubber hose of 19 mmOID to an overflow. Whereas in Test Stand 1 (Diagram 1) the levelling vessel and the water supply were so arranged that only a very weak spiralling motion at the inlet of the observation pipe was able to develop, in the case of Test Stand 2 (Diagram 2) the build-up of spiral motion was intentionally assisted by the trumpet-like form and a tangential inflow of water. The 40 mmOID test pipe with a flow section of 0.125 dcm2 was supplied with a quantity of water between 0.2 and 0.21 litres/sec, so that this would flow through at a calculated velocity of 1.6 to 1.68 dcm/sec. This already lies within the region of turbulent flow. A thin silk thread, weighted at the end, hanging straight down into the test pipe at a state of rest, was set

224

225

in a slow rotation corresponding to a slightly convoluted 3-dimensional space-curve by the flow of water through the pipe. In Test Stand 2 the curvature of the thread was greater than in Test Stand 1, due to the greater spiral motion at the inlet. Since apart from this, it was observed that fine hydrophobic suspensions, very evenly dispersed over the water surface with the aid of a finely meshed sieve, were concentrated into little clusters along the 3-dimensional space-curve denoted by the thread, it is thus demonstrated that a flow in the pipe is developed, which follows a 3-dimensional spiral curve and simultaneously rotates about the axis of this space-spiral. (Proof: Curvature and rotation of the silk thread.) This is also confirmed by the fact that the air entrained by the water becomes concentrated along the 3-dimensional space-spiral in the pipe and which, according to the size of the air bubbles in the rotating flow of the water about the space-spiral, either accompanies the water or rises upwards again.

In order to be able to examine this multiple in-winding flow more closely, the behaviour of three silk threads, each suspended from the corner of an equilateral triangular spacer-block, was investigated. Although the position of these threads was fixed by spacers at the middle and at the lower end as well, an entwining of the three threads could be observed, when water flowed through the pipe. In addition, the threads in this new arrangement were always forced into the region of the 3-dimensional space-spiral axis, despite their weighting and spacers. Due to the greater combined stiffness of the three entwined threads, which were even more encumbered than the single thread by their spacers and three end-weights, their curvature was naturally somewhat less than in the case of the single thread. In order to check whether the entwining of the three threads was not merely attributable to the rotation of the spacers caused by the rotation of the water at the inlet, the spacers were removed from the middle and the bottom. In this instance too, the entwining of the three threads and their alignment along a slightly curved space-spiral was achieved. It is thus clearly demonstrated, that the entwining of the threads cannot be ascribed to the rotation of the uppermost spacer, but only to the multiple in-winding flowing motion of the water.

This multiple in-winding flow process inside the pipe is superimposed by a second equally space-spiral-like, curving, peripheral motion as well. This phenomenon was made visible with the aid of iron filings. It was noticeable, that during the flow-through of the water in the pipe, the pitch of the strongly curved space-spiral is not constant, but gradually becomes greater and at the same time a concentration in larger agglomerations takes place.

These flow processes, which superimpose each other in pipes and which have been detected for the first time with the aid of the demonstrative experiments described above, must still be thoroughly investigated in relation to their formation and effect.

226

227

Were only centrifugal forces here active, then the silk thread hanging down the centre ought to have been drawn towards the exterior. Also such forces could never bring about an entwining of the threads along the weakly curved space-spiral. Moreover it would be impossible for centrifugally acting forces to twist the three silk threads suspended in the outer zones of the pipe into a single thread, which then further accommodates itself to the space-spiral-like curved axis. These phenomena can only be brought about by centripetally acting forces greater than the centrifugal force.

The multiple in-winding flow can therefore only be attributed to these centripetally directed forces initiated by the system of flow itself and which have been observed and clearly detected for the first time.

In addition, it can be concluded from the variable pitch of the strongly curved space-spiral and by the observed flocculation and migration of the particles of matter in the centre, that the centrifugal forces decrease with the flow-through of water in the pipes and the centripetal forces which overcome them are always of the same magnitude and accordingly increase their effect gradually in relation to the centrifugal forces.

The detected flocculative processes, however, cannot be attributed to the influence of mechanical forces alone. According to prevailing ideas concerning the coagulation of solids, it can be assumed with the greatest certainty, that the agglomeration of solid particles occurring in the course of the flow process, is triggered off by the effects of electro-physical forces.

The flowing motion of water in straight pipes, made visible in various ways, thus clearly proves that at the inlet of these pipes a greater or lesser spiraling motion develops, which in turn triggers off an in-winding flow along a space-spiral and which is additionally superimposed by flows along more strongly curved space-spirals. [from: The Energy Evolution - Harnessing Free Energy from Nature, pages 222-227]

228

[Return to The Energy Evolution - Harnessing Free Energy from Nature]

ChatGPT Analysis of Schauberger’s Dual Spiral Flows in Helicoid Pipe Designs [2/14/25]: [1] https://chatgpt.com/share/67af3ab6-f488-800d-8505-85126e39e457